Cantidad de pedido mínima:1

Modelo: 2-1

Marca: JCB

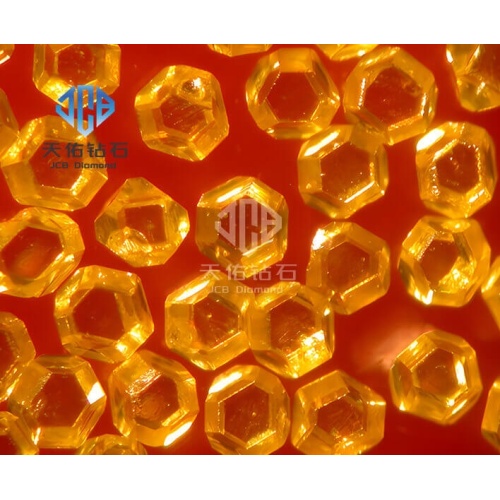

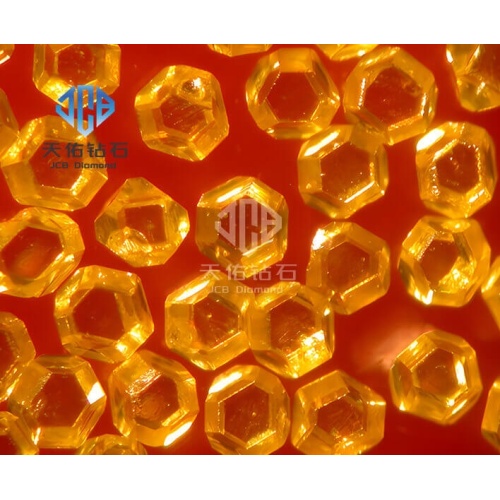

Diamante sintético grueso - Serie JSD

Los diamantes sintéticos gruesos de la serie JCB JSD están hechos para trabajos de servicio pesado que necesitan alta resistencia y durabilidad. Vienen en tamaños de grano de 20/25 a 50/60, tienen un color de color amarillo dorado, una forma de cristal completa, muy pocas impurezas y buena claridad. Estos diamantes ofrecen alta resistencia, resistencia al impacto y estabilidad del calor, lo que los hace ideales para usos industriales difíciles.

Obtenga más información: https://en.jcbdiamond.com/

Alta resistencia estática: maneja la presión extrema

Hardedad de impacto: no se agrietará cuando golpee

Estabilidad térmica: funciona bien incluso cuando está caliente

Baja impureza: alta claridad, funciona mejor

Resistencia al desgaste: dura mucho en trabajos difíciles

Herramientas de corte de diamantes : para cortar, moler y pulir materiales duros como piedra, concreto y cerámica

Herramientas de perforación geológica : ideal para perforación de alto rendimiento en condiciones difíciles

Sierras y equipos de perforación : usado en cuchillas de sierra de diamante, sierras de alambre y brocas

Herramientas de soldadura : bueno para la soldadura y la soldadura donde se necesita alta resistencia al calor

Construcción y minería : ideal para cortar concreto reforzado, asfalto y granito duro

La serie JSD se usa ampliamente en procesamiento de piedra, perforación de petróleo y gas, construcción y minería. Sus características fuertes los convierten en una mejor opción para trabajos que necesitan alta dureza, resistencia al desgaste y estabilidad de calor.

JCB JSD Diamantes gruesos sintéticos sintéticos varían en tamaño de 20/25 a 50/60. Tienen un color de color amarillo dorado, una estructura limpia, alta claridad y ofrecen un rendimiento fuerte bajo presión, impacto y calor. Se usan principalmente para hacer cuchillas de sierra de diamante, sierras de alambre, taladros de pared delgada, herramientas de molienda, brocas y herramientas de soldadura. Estos diamantes se usan comúnmente en trabajo de piedra, corte de concreto, construcción de carreteras y puentes, procesamiento de vidrio, perforación de aceite y mecanizado mecánico.

|

JSD90

Features: Complete and regular hexoctahedral crystal structure, almost no impurities within the crystal, extremely high static strength (Newton), impact toughness (TI), and thermal stability (TTI). Comprehensive performance meets international standards, with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, and brazing tools under extremely high working intensity conditions, such as cutting and drilling high-strength reinforced concrete, asphalt pavement, and extremely hard granite (F=20), as well as high-performance geological engineering drill bits. |

|

JSD80 Features: Complete and regular hexoctahedral crystal structure, very few impurities within the crystal, high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under high working intensity conditions, such as cutting and drilling reinforced concrete, hard granite (F=15), and high-hardness ceramic materials, as well as engineering drill bits. |

|

JSD70 Features: Relatively complete hexoctahedral crystal structure, few impurities within the crystal, relatively high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with good wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under relatively high working intensity conditions, such as cutting and drilling concrete, hard granite (F=10), high-grade tiles, and high-hardness refractory materials, as well as heavy-duty grinding tools and medium-to-high-load electroplating brazing tools. |

|

JSD60 Features: Relatively complete hexoctahedral crystal structure, relatively few impurities within the crystal, moderate static strength (Newton), impact toughness (TI), and thermal stability (TTI), with a balance of wear resistance and sharpness. Applications: Suitable for high-speed cutting and drilling under medium working intensity conditions, such as cutting and drilling non-reinforced cement pavement, hard marble, low-hardness granite (F=8), large quantities of building materials, refractory materials, and non-ferrous metal materials, as well as heavy-duty grinding tools and medium-load electroplating brazing tools. |

|

JSD50 Features: Relatively regular hexoctahedral crystal structure, moderate impurities within the crystal, average static strength (Newton), impact toughness (TI), and thermal stability (TTI), with moderate wear resistance and good sharpness. Applications: Suitable for high-speed cutting and drilling under medium-to-low working intensity conditions, such as cutting and drilling soft marble and sandstone (F=6-5), glass, ceramics, and batch building materials, as well as medium-load grinding tools and medium-to-low-load electroplating tools. |

|

JSD40 Features: 90-95% regular crystal structure, moderate impurities within the crystal, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with average wear resistance and excellent sharpness. Applications: Suitable for high-speed cutting and drilling under low working intensity conditions, such as small-diameter free-cutting drilling tools, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

|

JSD30 Features: 85% regular crystal structure, more impurities within the crystal compared to JSD40, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and excellent sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, such as cutting and drilling gemstones, jade, crystal, and other high-brittle materials, as well as small batches of stone, glass, and tiles, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

|

JSD20 Features: 70% regular crystal structure, relatively high impurities within the crystal, rough surface, low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and extremely high sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, medium-to-high-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |

|

JSD10 Features: 50% regular crystal structure, high impurities within the crystal, rough surface, very low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with very poor wear resistance, extremely high sharpness, and good self-sharpening properties. Applications: Suitable for medium-to-high-load resin bond tools, medium-to-low-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |